Digital twin for the win.

Highly accurate data capture, digital twin and 3D model services.

dig•i•tal twin

Imagine a 3D model with a built-in record of designs, systems and dimensions. A digital twin is a representation that serves as a real-time digital counterpart of a physical object or process, such as a building or manufacturing facility.

Real time data means better decisions.

Minimize overages, avoid clashes and improve profits.

Top of the line 3D equipment & scan technicians

Equipment for any application & level of detail

Time saving details & precision measurements

High quality workmanship & collaboration

HOW IT WORKS

We Focus, You Win.

1

Project Customization

Each project is customized based on the type of site, the application, and the level of detail (LOD) needed. The equipment, cameras and cost changes with the LOD. Site surveys typically are high LOD while space planning needs lower LOD.

3

Better Decisions

3D models save time and minimize change orders. Documenting as-built conditions is invaluable for renovations, estimating, safety and simulation. Better decisions lead to increased profits and minimized overages for contractors, MEP professionals, building owners and design professionals.

2

Capture & Processing

Trained capture crews are deployed to the site with 3D scanning equipment for the LOD & application. Every detail & angle is scanned with precision capture equipment. Millions of data points are combined and processed into a point cloud or converted into a 3D model or digital twin.

Get started today with a consultation.

Schedule a consultationServing your industry.

Leverage the power of 3D & reality capture.

BIM Modeling

Utilities & Energy

Construction Documentation

As-Built Documentation

Manufacturing & Industrial Plants

Historical Architecture

Project Win

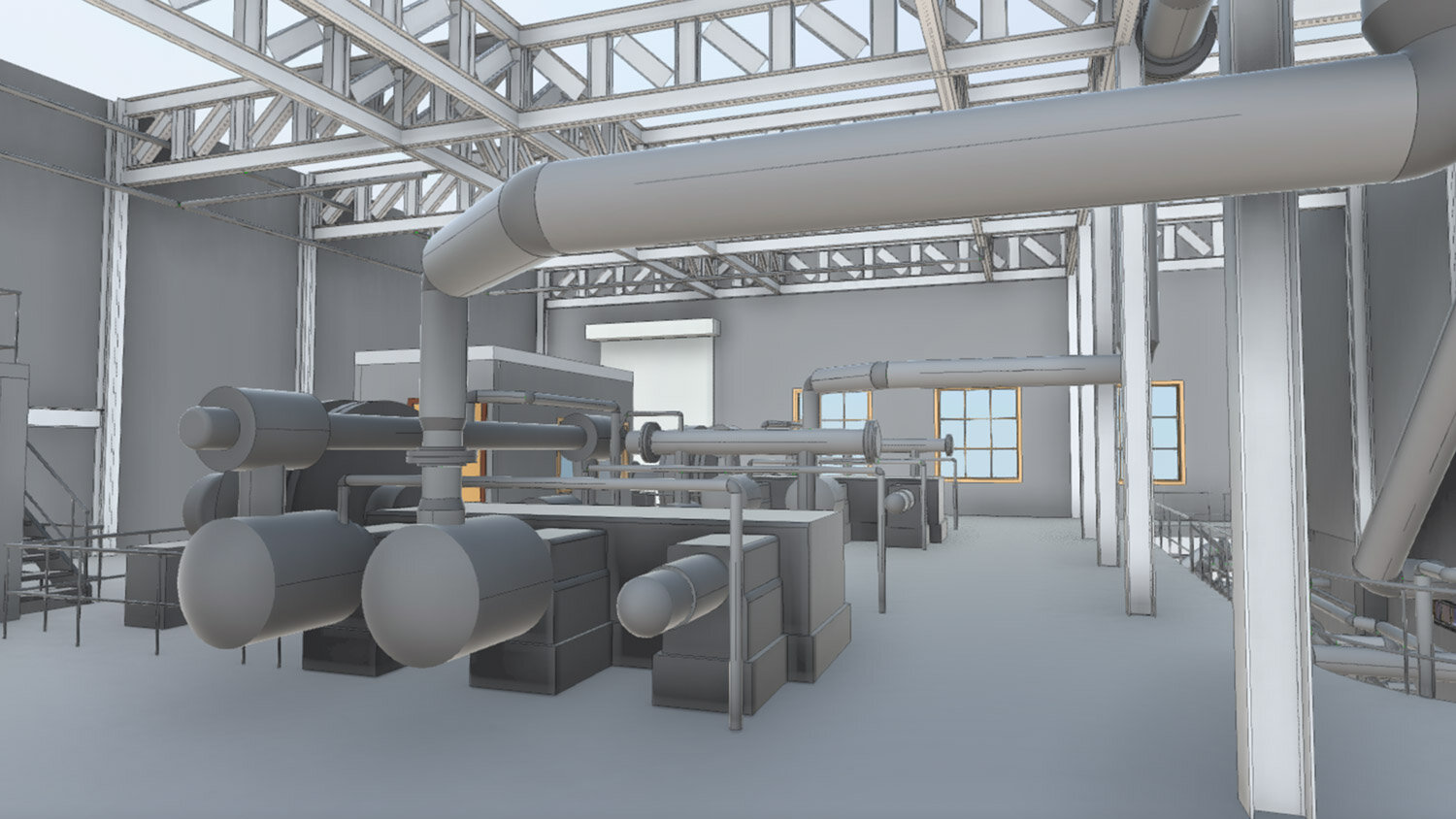

A pharmaceutical manufacturing plant in North Carolina was undergoing an expansion of the facilities. A digital twin was created to assist with redesign of the integration of the existing MEP infrastructure with the redesign. Data from the scans was converted into a Revit model that the design firms utilized for layout of the new systems.

Challenge

A pharmaceutical manufacturing plant was undergoing a retrofit to improve plant operations. The existing electrical and mechanical infrastructure needed to integrate with the new needs of the plant. Routing of the newly designed systems would have to be implanted without clashing with existing systems that were in place.

Solution

360pro crews did a series of terrestrial laser scans of the plant to create a point cloud. This point cloud was then used to create a Revit model. Engineers were able to import the 3D model into their ecosystem and software, which enabled them to map and route the new electrical systems within the existing infrastructure.

Win

Integrating the old and new mechanical systems saved thousands of dollars and greatly reduced the risk of delays and mistakes. Using the 3D model engineers, technicians and project managers saved time and reduced site visits with virtual access to measurements and dimensions. Materials were able to be ordered to specifications and delivered to the site ready for install.